Frequently Asked Questions

New Technology Development Directive

In an industry that has not been able to adapt efficiently to environmental standards, it is important to educate our clients and their communities. We provide complete transparency of our services and product, including implementation, management, and general instruction.

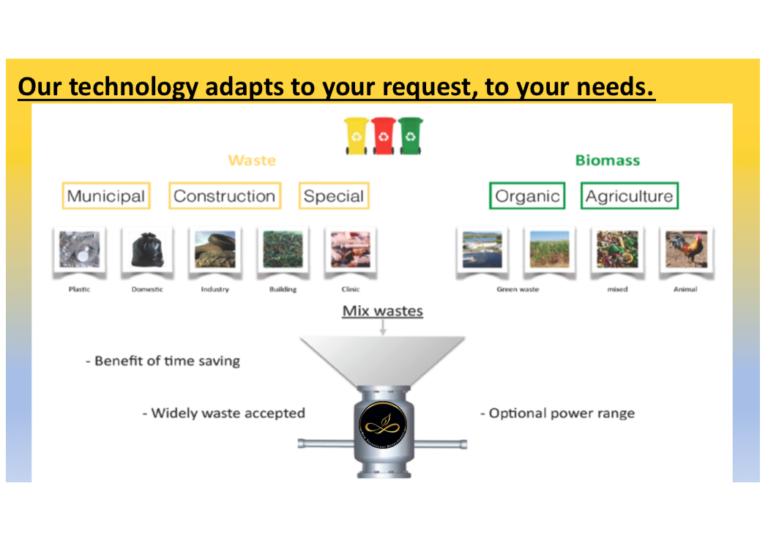

What waste does your machine eradicate?

We can treat almost all waste, including domestic municipalities, micro, and nanoparticles plastics, industrial construction, biohazardous such as hospital waste, and organic waste such as agricultural and animal waste.

What waste is not able to be treated?

How is the waste eradicated?

Our machine uses a thermal process by gasification. The thermal treatment technique is a process that is an alternative to the present-day widely used incineration technique, more known as the burning of waste. During incineration, the destruction of waste requires the presence of excess oxygen to produce high temperatures. Inversely, gasification is the breakdown of debris with a limited presence of oxygen due to the enclosed setting. Instead, it is based on the decomposition of the residual materials under extreme temperatures.

What is the product or environmental output of your treatment process?

Through our thermal treatment process, gasification takes place in a closed setting. Thus, there will not be any odor or smoke externally. Within the machine, syngas is released. Syngas is a mixture of hydrogen and carbon monoxide in various ratios determined by the amount of waste. Our syngas production is rich in hydrogen and much less C02 excess than currently used treatments. Moreover, due to an enclosed setting, the syngas can be redirected to contribute to the production of usable energy. Once the process is complete, the minimal residue recovered is vitrified rock crystal, 1 kilogram per 1,000 kilograms treated, which is eco-friendly and can be used in construction or pavement material.

Is your process scalable?

Yes, indeed, our process is scalable! We have strategies to apply it as renewable energy for the typical household to city-wide municipality use. Please feel free to contact management to find out how to personalize our technology for your community needs!

How is your product delivered?

NTD machines are manufactured, delivered, and installed in 20 feet-insulated containers. With the optional maintenance contract proposed, trained NTD treatment service can be provided to ensure it operates at superior quality.